In the rapidly expanding aquaculture sector, particularly in shrimp farming, the quality of feed is crucial for the success and profitability of operations. Central to high-quality shrimp feed production is the shrimp feed pellet machine. Choosing the right shrimp feed pellet machine is essential for achieving optimal feed quality, production efficiency, and cost-effectiveness. This article delves into the key features that define the best shrimp feed pellet machines and offers guidance on making an informed decision.

Key Features of Top Shrimp Feed Pellet Machines

High Production Capacity:

The best shrimp feed pellet machines boast high production capacities without compromising pellet quality. Leading machines can produce between 2 to 20 tons per hour, catering to the demands of large-scale shrimp farming operations efficiently.

Precision in Pellet Size and Uniformity:

Shrimp at various growth stages require different pellet sizes. Top machines provide easy adjustability in pellet size, typically ranging from 0.9mm to 3mm in diameter, and ensure uniformity in size and shape. This uniformity is vital for even feed distribution and optimal feed conversion ratios.

Excellent Water Stability:

Since shrimp are slow feeders, pellets must maintain their integrity in water for extended periods. The best shrimp feed pellet machines produce pellets with excellent water stability, lasting 4-6 hours without disintegrating. This is achieved through optimal conditioning and extrusion processes.

Energy Efficiency:

With rising operational costs, energy efficiency is a critical factor. The best machines incorporate energy-saving features such as efficient motors, optimized gear transmissions, and smart control systems that reduce power consumption without sacrificing performance.

Advanced Conditioning Technology:

Effective conditioning is essential for producing high-quality shrimp feed pellets. The best machines feature advanced conditioning systems, including double-shaft conditioners or multi-stage conditioning processes. These systems ensure thorough mixing, proper moisture addition, and optimal starch gelatinization, leading to enhanced pellet quality and digestibility.

Durability and Low Maintenance:

High-quality shrimp feed pellet machines are constructed to endure, using wear-resistant materials for critical components like dies and rollers. They are designed for easy maintenance and quick part replacements, minimizing downtime and maintenance costs.

Flexibility in Ingredient Processing:

The best machines can handle a variety of ingredients, including plant-based proteins, fishmeal, and various additives. This versatility allows feed producers to adjust formulations based on nutritional requirements and ingredient availability without compromising pellet quality.

Advanced Control Systems:

State-of-the-art control systems, often featuring touchscreen interfaces and PLC (Programmable Logic Controller) integration, are hallmarks of the best shrimp feed pellet machines. These systems enable precise control over processing parameters, real-time monitoring, and data logging for quality assurance.

Hygiene and Safety Features:

Given the importance of feed hygiene in shrimp health, the best machines incorporate features that facilitate easy cleaning and prevent contamination. They also include comprehensive safety measures to protect operators and comply with industry standards.

Scalability and Integration:

Top shrimp feed pellet machines are often modular in design, allowing for easy scaling of production capacity. They also integrate seamlessly with other equipment in the feed production line, such as mixers, dryers, and coolers.

Leading Manufacturers and Models

While specific model recommendations can change due to technological advancements, several manufacturers consistently produce high-quality shrimp feed pellet machines:

- Bühler: Renowned for high-capacity extruders and pellet mills, Bühler’s machines are favored for large-scale operations.

- Andritz: Their ANDRITZ Paladin series pellet mills are recognized for producing high-quality aquatic feed, including shrimp feed.

- Muyang: The MUZL series pellet mills from Muyang are highly regarded for their efficiency and pellet quality in aquafeed production.

- Clextral: Known for twin-screw extruders, Clextral produces high-quality floating and sinking aquafeed pellets.

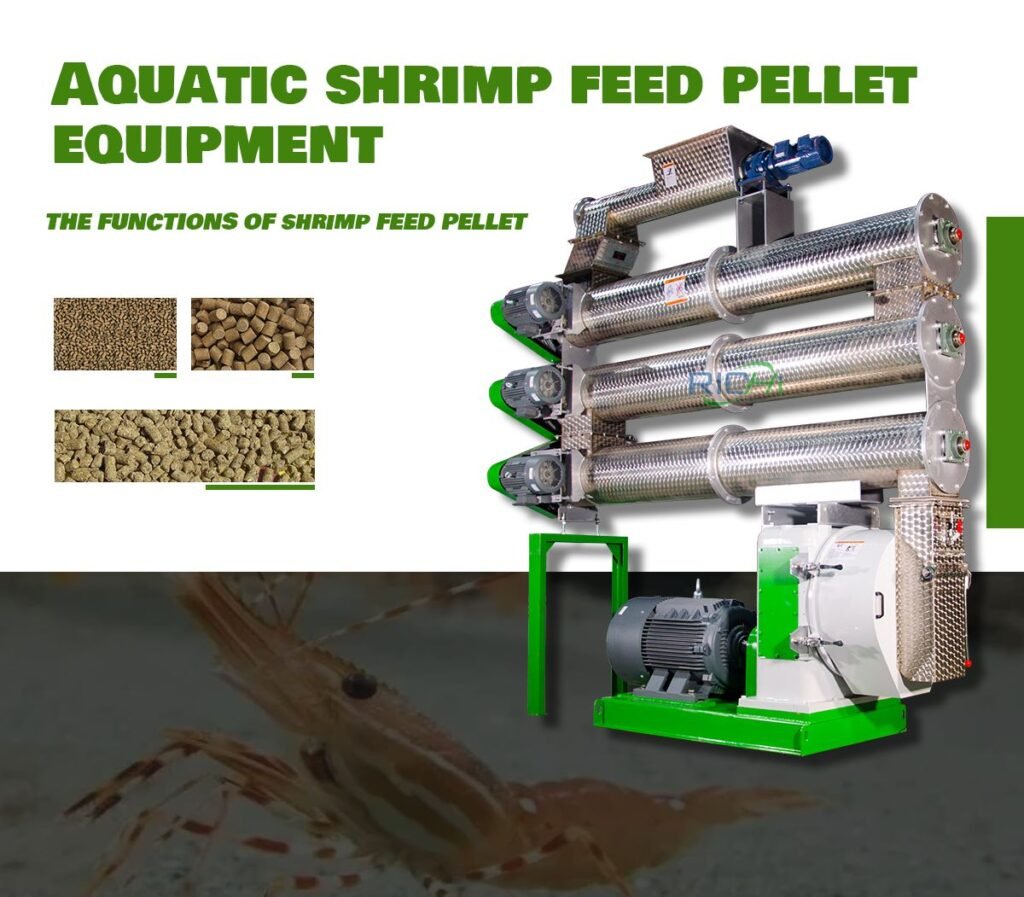

- RICHI Machinery: Their shrimp feed pellet machines excel at handling high moisture content and producing pellets with excellent water stability. (Related post: shrimp feed plant)

Factors to Consider When Choosing a Machine

When selecting the ideal shrimp feed pellet machine for your operation, consider the following factors:

- Production Capacity: Ensure the machine’s capacity aligns with your current and future production needs.

- Feed Formulation: Evaluate the types of ingredients you intend to use and ensure the machine can process them effectively.

- Pellet Specifications: Confirm that the machine can produce pellets of the required size and density for your specific shrimp species and growth stages.

- Energy Consumption: Compare the energy efficiency of different models, as this can significantly affect operational costs.

- Maintenance and Support: Assess the availability of spare parts and technical support in your area.

- Budget: While the initial cost is important, consider long-term operational costs and potential return on investment.

- Compliance: Ensure the machine meets relevant industry standards and regulations in your region.

Conclusion

The best shrimp feed pellet machine combines high production capacity, precise pellet formation, energy efficiency, and durability while producing pellets with excellent water stability and nutritional integrity. It should also provide flexibility in ingredient processing and integrate advanced control systems for optimal operation.

Manufacturers like Bühler, Andritz, Muyang, Clextral, and RICHI Machinery are known for producing high-quality machines. However, the “best” machine for any specific operation will depend on unique needs, production scale, and local conditions.

Ultimately, selecting the right shrimp feed pellet machine requires careful consideration of your specific requirements, thorough research, and possibly consultations with industry experts or machine manufacturers. By investing in a high-quality shrimp feed pellet machine, you can ensure superior feed production, leading to healthier shrimp, improved feed conversion ratios, and, ultimately, a more profitable and sustainable shrimp farming operation.